Global Supply SystemGLOBAL SUPPLY SYSTEM

We develop our business through

12 locations in Japan and 10

oversea locations.

Whether domestic or overseas,

we are developing linked production,

international collaboration and

support activities to ensure

that responsibility

is taken to manufacture and

supply products with Sango quality.

Expanding "Sango quality" and supply system globally

Linked production

In order to realize efficient and speedy production, we promote cooperative production activities with affiliated operations in the supply sector.

International collaboration

In overseas area where we do not have our own production facility, Sango works with partner companies. We provide technical assistance and entrust them with the manufacture of the product.

Support activities

In order to take responsibility for the product's Sango quality, technical assistance and quality kaizen (continuous improvement) guidance is provided to domestic and overseas production facilities and partner companies.

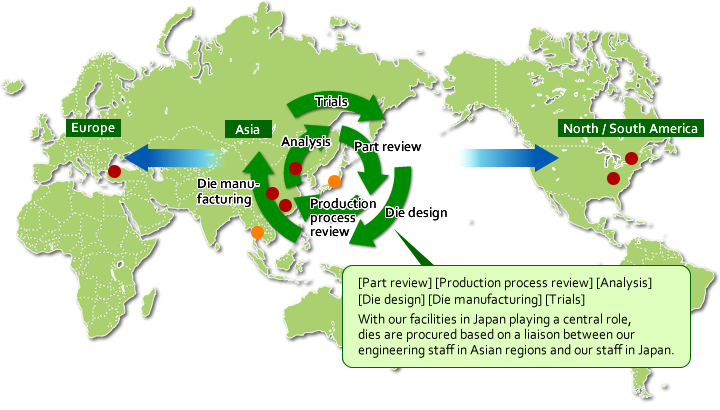

Global supply system for dies

Based on our technical skills finely honed over many years in Japan and with the combined use of CAD, CAE, CAM and other equipment with the latest technology both in Japan and abroad, we are able to manufacture high quality dies which are used in our various production facilities around the world.

Sango's engineering capabilities

●Production system of dies: a coherent process provided from initial inquiry to in-house trial

●Shortened delivery period of dies: as a result of long years of experiences and fine-tuning techniques achieved by original precision analysis in manufacturing processes.

●Reverse engineering: parts production by generating data from forms of parts that are already made.

Die manufacturing plant in Japan (within the premises of the Fukuta Plant)

Die manufacturing plant in Thailand (within the premises of STEM)