Exhaust Systems

We offer wide range of exhaust system

products such as new developed products

with application of spinning and heat utilization,

exhaust manifold,

catalytic converter, heat collector and muffler.

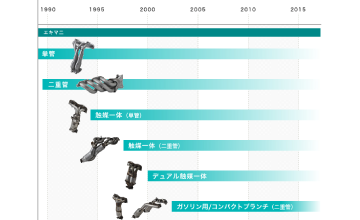

Product portfolio

Exhaust manifolds

■Exhaust manifolds for high engine performance

To obtain durability, black paint coating is applied to radiate heat from the exhaust manifold.

■Exhaust manifolds with close-coupled converters (premium cars)

With ultra-small radius bending and spinning, this manifold is made to be compact.

■Exhaust manifold with integrated air injection system

This exhaust manifold is made suitable for integrated air injection system.

■Air gap manifold

By designing the exhaust manifold with an inner pipe and an air gap between the two pipe layers for lower heat capacity, even better catalytic conversion is achieved. This is a design with the environment in mind.

Engine parts

■EGR pipe

We improve the durability of pipe for exhaust gas recirculation with the use of flexible pipes.

■Diesel Particulate Filter

This is a system to trap exhaust particles from diesel engine. Sango's original PRS sizing technology allows it to keep high filtration rate.

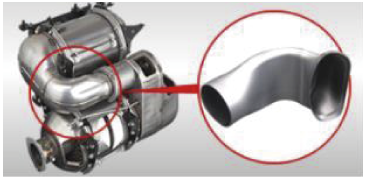

■Turbo elbow

It utilize ultra-small radius bending and spinning technologies.

■Diesel Oxidation Catalyst

By application of flexible tube and wire blade to absorb vibration, we improve its durability.

Heat Recovery / Heat Utilization Products

Catalytic Converters / Emission Control Products

■Spin-formed catalytic converters

Using a spin-forming process, we are able to manufacture catalytic converter cases from a single piece of material.

■Catalytic converter canning made with sizing

This processing technique allows us to carry out highly accurate canning for diesel particulate filters (DPF), which require higher catalyst retention strength.

■Tandem catalytic converter (Stepped shape processed in a one piece structure)

Two substrates of differing cross-sections (an oxidation catalyst and a filter) are canned in a single integrated case.

■Urea SCR exhaust aftertreatment system

In response to stringent emissions regulations, this system contains elements with large diameter inlets/outlets, including an oxidation catalyst, DPF and SCR.

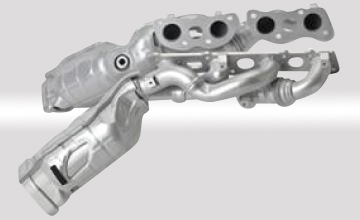

■Diesel exhaust manifold with particulate filter

Within a limited space, it is designed to place exhaust manifold, oxidation catalyst, and DPF effectively. This clean diesel system meets strict emissions regulations.

■Exhaust manifolds with close-coupled converters (small cars)

By warming up the catalyst faster with the application of air gap pipes and exhaust manifolds with close-coupled converters, it contributes to filtrate emissions.

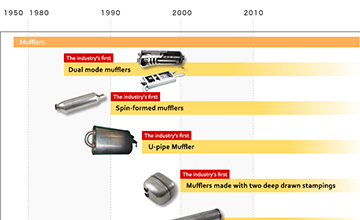

Mufflers

■Spin-formed mufflers

The entire muffler shell can be made from a single piece of material, without the use of welding and at lower cost. Besides straight spinning, muffler cones can be spun in eccentric or oblique designs.

■Dual mode mufflers

(internal valve)

By changing the exhaust gas flow within the muffler, we can achieve both the silencing of exhaust noise and lower back pressure, and with 20% less volume than a standard conventional muffler. It is operated solely by exhaust gas pressure.

■Sports mufflers

With some expert tuning of the muffler and pipes, this aftermarket muffler provides consumers with the powerful, sensuous sound they desire, while also improving engine.

■Lock-seam mufflers

The muffler case is constructed with mechanical crimping (no welding).

■Laser welded mufflers

Higher levels of productivity are achieved with the construction of muffler cases using laser welding.

■Stamped shell mufflers

By making muffler cases from stamped components, it allow us to reduce the number of components needed to build the muffler.

■Titanium mufflers

Muffler weight is significantly reduced with the use of titanium material.

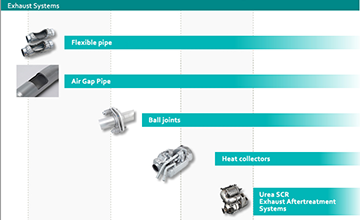

Exhaust System Products

Sango is a system integrator that supply products finding optimal combination of various parts to form a working system.

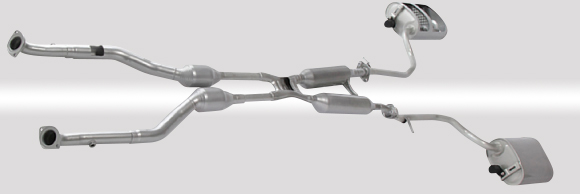

Premium vehicle exhaust systems

■Completely dual exhaust system providing both quietness and good engine performance

Applied Technologies

Dual mode mufflers, Spin-formed mufflers, Lock-seam mufflers, Spin-formed catalytic converters, Air Gap Pipe, Ball joints

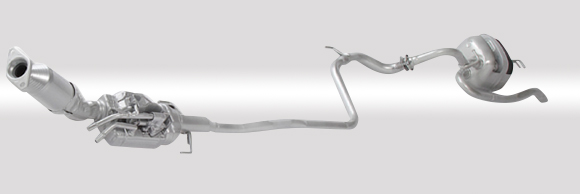

Small car exhaust systems

■Exhaust systems designed for compactness and light weight

Applied Technologies

Laser welded mufflers, Catalytic converters (made with spin forming), Ball joints, O2 sensor bosses

Small hybrid car exhaust systems

■Exhaust systems equipped with heat collectors

Applied Technologies

Heat collector, Dual mode mufflers(internal valve), Stamped shell mufflers, Spin-formed catalytic converters, Ball joints, O2 sensor bosses

Sports car exhaust systems

■Exhaust system sound tuning with titanium mufflers

Applied Technologies

Sound timbre development, Titanium mufflers, Dual mode mufflers(internal valve), O2 sensor bosses

Exhaust System Components

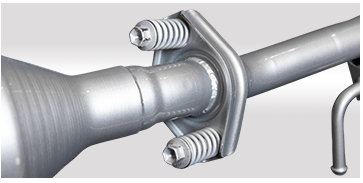

■Vibration isolation devices

These devices reduce exhaust system vibration and help improve durability.

■Air gap pipe

The air gap pipe bending products help with early light-off of the catalytic converter, as well as prevent heat damage to surrounding components.

■Tail pipe trim

We offer flat outlet and sharp angle designs. These products help cool the exhaust gas and some provide acoustic silencing functions.

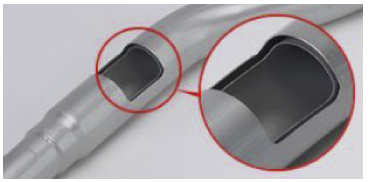

■Hydroformed pipe

With the use of hydroforming, it is possible to form exhaust gas paths with irregular cross-sections and complicated bends integrated into a single component made from one piece of material.

■O2 sensor bosses

Sintering (powdered metal) allows a high degree of freedom in shape design.