Wire Material ProcessingWIRE PROCESSING

We offer a coherent process design from wire material treatment to cold forging.

This allows us to meet challenges to produce complex metal working products and to reduce total cost.

Secondary Steel Products from Wire Material

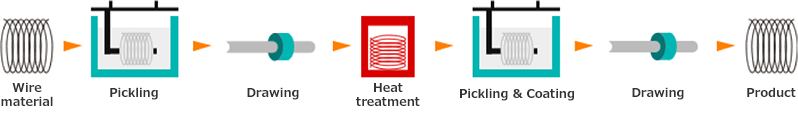

Using wire as the raw material, after a pickling process to remove scale and coat the wire, it goes through a cold drawing process and the finished product is once again put into a coiled state. By combining heat treatment, wire drawing, and coating processes, Sango provides the right material for the customer's following process.

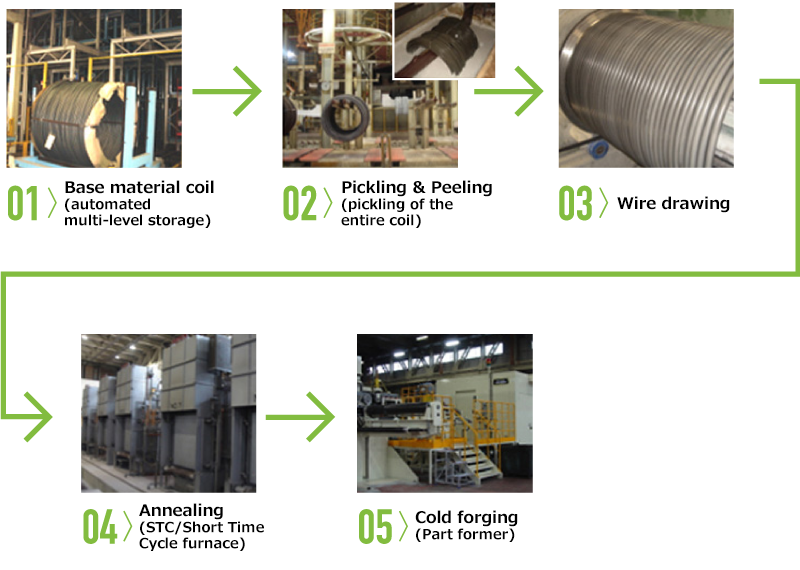

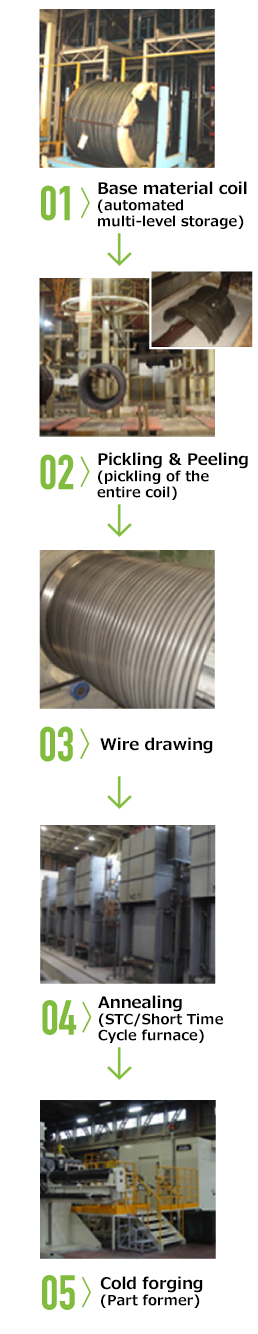

Outline of the process

Photographs of the processes

Heat treatment

Pickling & Coating

Drawing

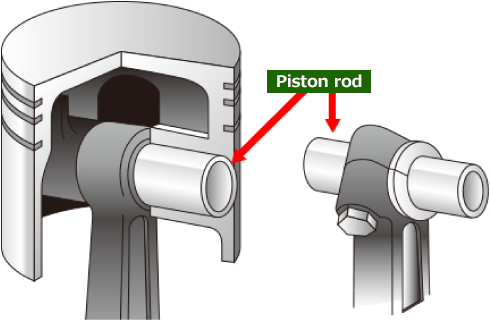

Manufacturing process of Piston rod

Because the integrated processing approach begins with the raw steel wire material, Sango is able to carry out joint development of the steel for this raw material with the steel manufacturer, making it possible to provide new product ideas for our customers. We use our high tech know-how to supply customers with a diverse range of steel material, allowing them to match the right material for their needs.