Production SystemPRODUCTION SYSTEM

Our task is to supply the customer with the best possible goods without error.

Not just the functional components, but also from the component material to the anchoring parts,

such as a mating part that fits to the component, by retaining a completely unifies production system,

we can realize the stable supply of high quality, low cost products.

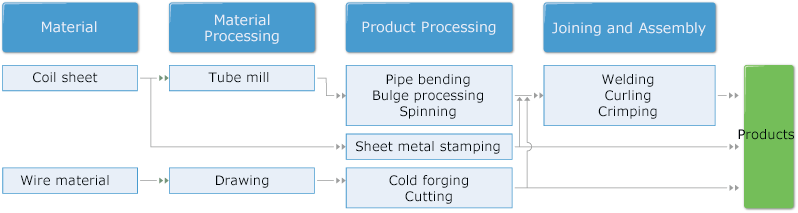

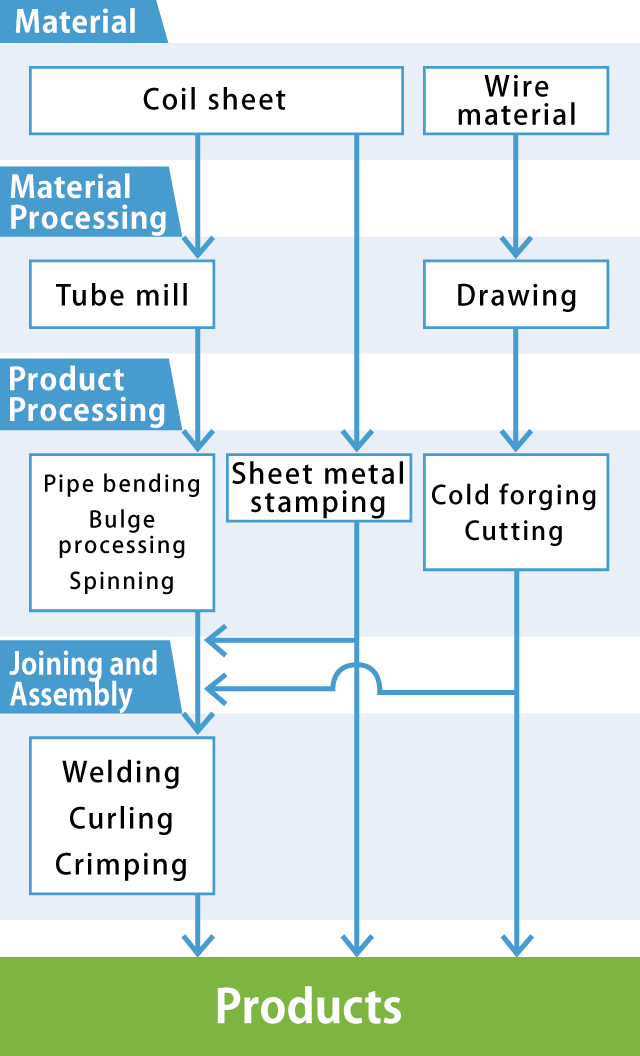

Integrated production system

The fully integrated production at Sango begins with the manufacture of materials such as tubing and stamped parts, finishing with the final product: a complete exhaust system.

Processing Examples

Tubing

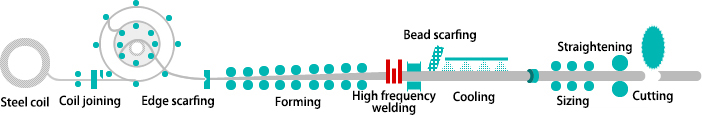

■Outline of the process

■Photographs of the processes

Forming process

Forming rolls

High frequency welding

"Roll flower"

Using steel coil for tube mills, the steel is first formed and then welded in a high frequency induction welding process to form a tube. After this, in one continuous process, the inner and outer weld bead surface is removed (bead scarfing), the tubing is straightened and cut into the finished product. Sango's own unique production system makes it possible to produce in small lots and also to manufacture tubes from special steels, such as stainless steel. Because the forming process looks like flower petals when viewed fragmentally, we call this forming roll trace a "roll flower".

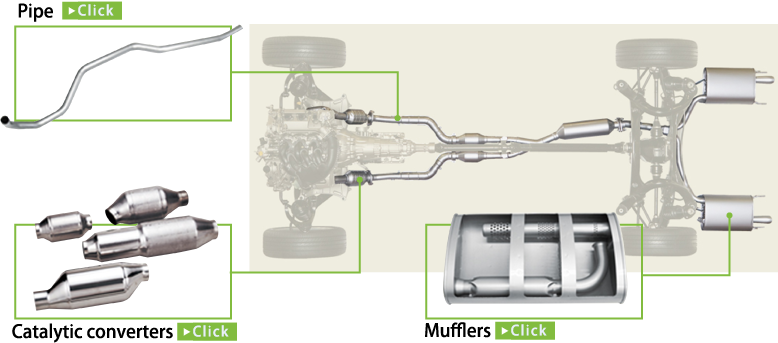

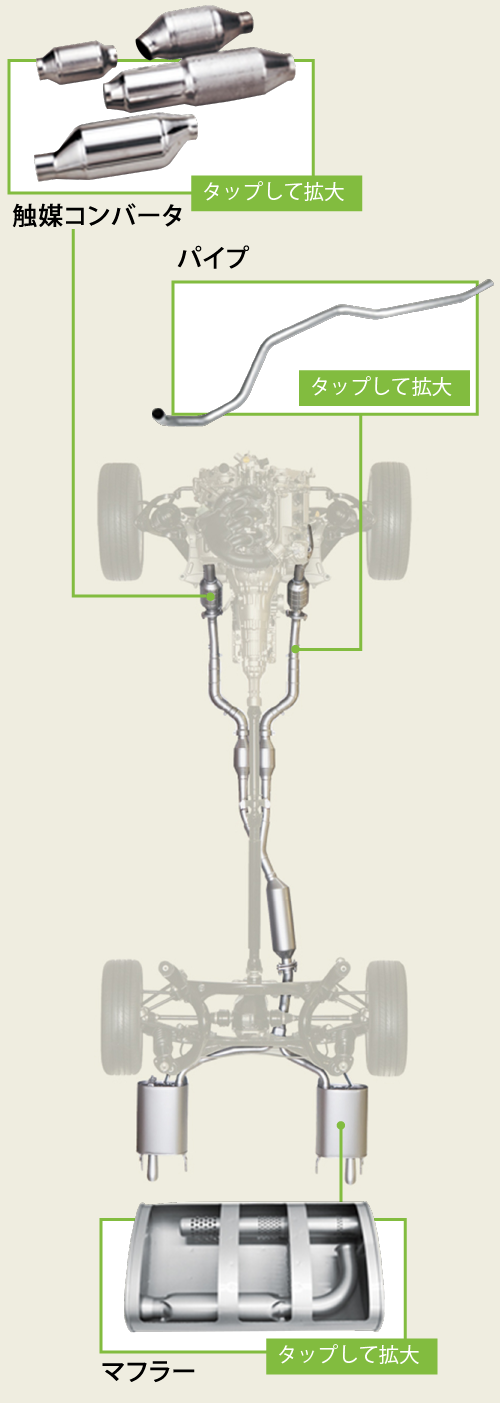

Exhaust systems

Several components made from row material such as coil sheet are assembled into an exhaust system.

Production facilities

■Transfer press

■Hydroforming press

■Progressive press